500mm Plantable Smc Manhole Cover For Green Field

Halogen-free, environment friendly, load class A15(1.5t).

About 500mm Plantable SMC Manhole Cover For Green Field:

The recessed plantable manhole cover series is new arrival and designed for greenfield that requires hidden functionality and light duty of load bearing capacity, usually less than A15. The lid is designed with two lifting holes on the rim and five drainage holes on the bottom. It is widely used in green land construction projects. Compared with ordinary sewer manhole covers, manhole cover for green field has the function of invisibility, and has the effect of inspection and beauty.

Outstanding Features of SMC Manhole Covers:

① SMC manhole covers have smooth and beautiful appearance, with many optional colors (black, gray, green, yellow, red). The cover surface is designed to be anti-skid and with delicate patterns and lines, product surface can be customized design.

② Lightweight. The weight of glass reinforced plastic manhole cover is 1/3 that of a cast iron manhole cover or cement manhole cover. So that SMC manhole cover is easy for one man operation, more convenient for daily inspection and maintenance, also can reduce the risk of labor injury.

③ Fiberglass has excellent toughness and are not easy to crack. The load bearing capacity can be graded up to A15/B125/C250/D400/E600/F900 according to standard of EN 124-1:2015, EN 124-5:2015.

④ Anti-corrosion and anti-aging, resistant to any harsh weather conditions. The properties of the fiberglass themselves give the products excellent high and low temperature resistance (the products can be used at -50~160℃), chemical resistance (acid, alkali, salt, organic solvent, etc.) and dimensional stability (very low coefficient of thermal expansion: 12*10-6/℃).

⑤ Compared to metal, the SMC material is with remarkable insulation and excellent dielectric performance. Through the improvement of the formula so that the product has excellent anti-static performance and fully meet the electronic industry SJ/T11159-1998 floor covering and assembly floor electrostatic performance requirements. Also, composite material is non-rusty, no scrap value and less noise.

⑥ Long service life. Through the use of high performance resin, glass fiber and special production process formula, to ensure the resin penetration in glass fiber, greatly enhance the internal adhesion, so that the product has a high fatigue strength, under the action of a given effective load and frequency, its service life is usually not less than 30 years.

⑦ Environmental-friendly. The raw materials used are halogen-free, SMC is non-toxic products. The reasonable structural design solves the noise problem caused by the impact between the cover and the frame.

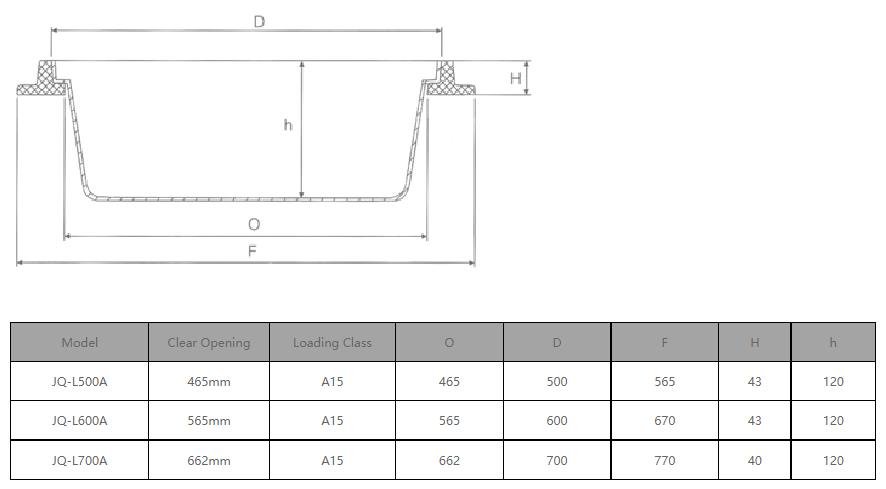

Dimensions:

Product Application:

Production Capacity and Inventory: