JQ Composites

Quanzhou JieQiang Road Facility Co. was founded in 2007, That is the starting point for us to escort the traffic safety of Chinese urban roads. In 2008, the new press machine of 500 tons and SMC sheet production equipment improved the production efficiency and the products quality.

In 2010, the factory moved to TaiShang Industrial Park to expand the scale of production. 2011, JQ officially entered the tap water system to provide water meter boxes for thousands of households water supply and security.

In 2013, the BMC manhole cover was replaced with SMC manhole cover, that greatly improved safety factor of urban roads. In 2014, SMC flower boxes started contributing to the greening of elevated roads and the beautification of urban landscapes.

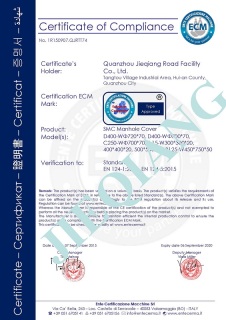

In 2015, our manhole cover products began to enter the international market. The first manhole cover was exported to Europe from XiaMen Port, that was the opening of our global market strategy. After these 7 years, JQ manhole cover has been laid on the roads of more than 30 countries and regions in the world and provides road security.

In 2018, the latest 1500 tons of large press machine was introduced for further expanding the scope of production. In 2019, JQ independently designed and developed the fuel station manhole cover and officially entered the global fuel station supply system.

In 2020, the latest introduction of automatic SMC production equipment.

In 2021, the company began to layout a number of branches and offices at home and abroad.

On May 8th, 2022, JQ Company celebrated its 15th anniversary in JiuXianShan moutain in Dehua County of Quanzhou City.

JQ Composites provide efficient supply services in the whole chain from product design, molds design, raw material preparation, SMC production, molding compression, finish product assembly, quality control, sales management, after-sales service. The factory is equipped with two sets of semi-automatic sheet moulding compound production equipment line, and the daily production of SMC can reach more than 60 tons; The two main workshops are equipped with more than 20 high-tonnage hydraulic press machines, with molding pressures ranging from 315 metric tons to 2000 metric tons, and the largest press machine is capable of producing over 2 meters in diameter of the molded products. The two laboratories in our factory can independently complete the common performance coefficient tests of composite products, including load class, deformation, toughness, rigidity and other required standards. At present, there are more than 1000 sets of molds to produce existing composite products.

JQ Company is committed to providing clients with high-end customized fiberglass products and services with high quality materials and advanced technology. It has become a long-term partner of municipal engineering, electric power telecommunications, real estate development zones, as well as major building materials agents, and has established a good brand image in foreign markets. Our products have passed ISO 9001 quality management system certification, ISO 14001 environmental management system certification, and European CE certification.