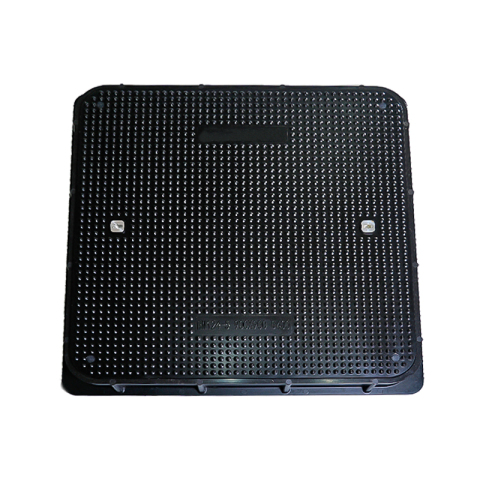

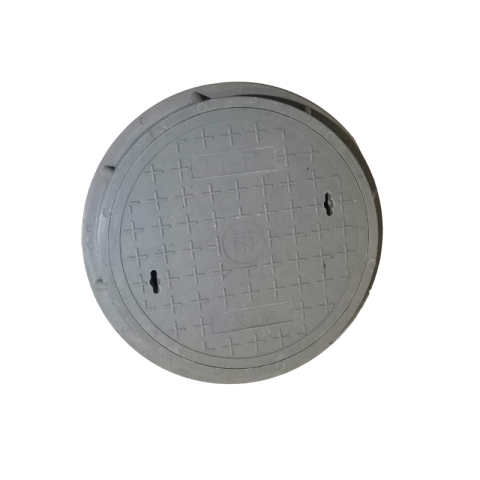

Products

About Us

JQ Composites

JQ Composites provide surficient product types and supporting services for retail fueling and oil companies. The factory is equipped with two sets of semi-automatic sheet moulding compound production equipment line, and the daily production of SMC can reach more than 60 tons; There are 20 high-tonnage hydraulic press machines with molding pressures ranging from 315 metric tons to 2000 metric tons, and the largest press machine is capable of producing over 2 meters in diameter of the molded products. With two laboratories in our factory can independently complete the common performance coefficient tests of composite products, including load class, deformation, toughness, rigidity and other required standards.

Our Advantage

Maintain product variety expansion and technological innovation

JQ composite molded products have been widely applied in municipal roads, sidewalks, real estate, communications, water, chemical, pipeline gas, heat, electricity and many other industries. With the accumulation of industry experience combined with the changing market demands, we add more new types of products and update the product series step by step, and meanwhile we've been doing continuous trials, R&D and improvement both from the material and structure design to some series of product, as we target to make perfection more perfect. In addition to the existing mass-produced product types, GRP molded products can be used in a wide range of applications, including fan blower shell, fan blades, wires frame, satellite receiver shell, ceiling board, etc. We have sufficient experience in product customization to meet customer's individual needs.

Stable management to ensure product quality and after sales service

Since 2007, with more than 16 years of continuous development, we've built a stable team to apply skilled technique and advanced machines for continuous and steady production. Our factory has been maintaining stable cooperation with outstanding raw material suppliers with stable production, that guarantee our stable and continuous production even when the raw materials are easily in short supply or when the price of crude oil soared.

High tonnage hydraulic machine with thermal compression technology

As a molded product manufacturer with more than 16 years of industrial experience, we've put a lot of effort into the best combination of product design and mold making, that means it's significant to find some professional mold making company and have long term relationships with them. We choose the most suitable mold factory to design and make the best moulds for our products with considering about product sizes, design complexity, delivery time, order budget, etc..

Independent production of high-quality SMC/composites for specific products

1, It can maintain good dielectric performance under high frequency, and does not reflect or block the microwave. It is suitable for application in crowded or narrow places, and can effectively avoid the danger of electric shock.

2, It has effective resistance to water, gasoline, alcohol, electrolyte salt, acetic acid, sodium potassium compounds, asphalt, acid base soil and acid rain corrosion.

3, Under the combined action of three-dimensional network molecular structure and reinforcing fiber, the material has good impact resistance, easy to be machined, easy to drill and cut, and accurate positioning.

FAQ

What are the core advantages of SMC materials and products?

SMC (Sheet Molding Compound) products have the characteristics of high strength, corrosion resistance, good insulation, light weight, high design freedom, and short molding cycle, and are suitable for fields such as manhole covers, automotive components, and electrical enclosures.

What is your after-sales services?

1, The main products have more than three years of warranty.

2, Accessories or fittings for composite products attached to main products choose a longer warranty period depends on vulnerability.

Can we have our logo on the product or on package?

Before mould opening, you can determine your own pattern on product surface or appearance and logo on carton packaging can be customized.