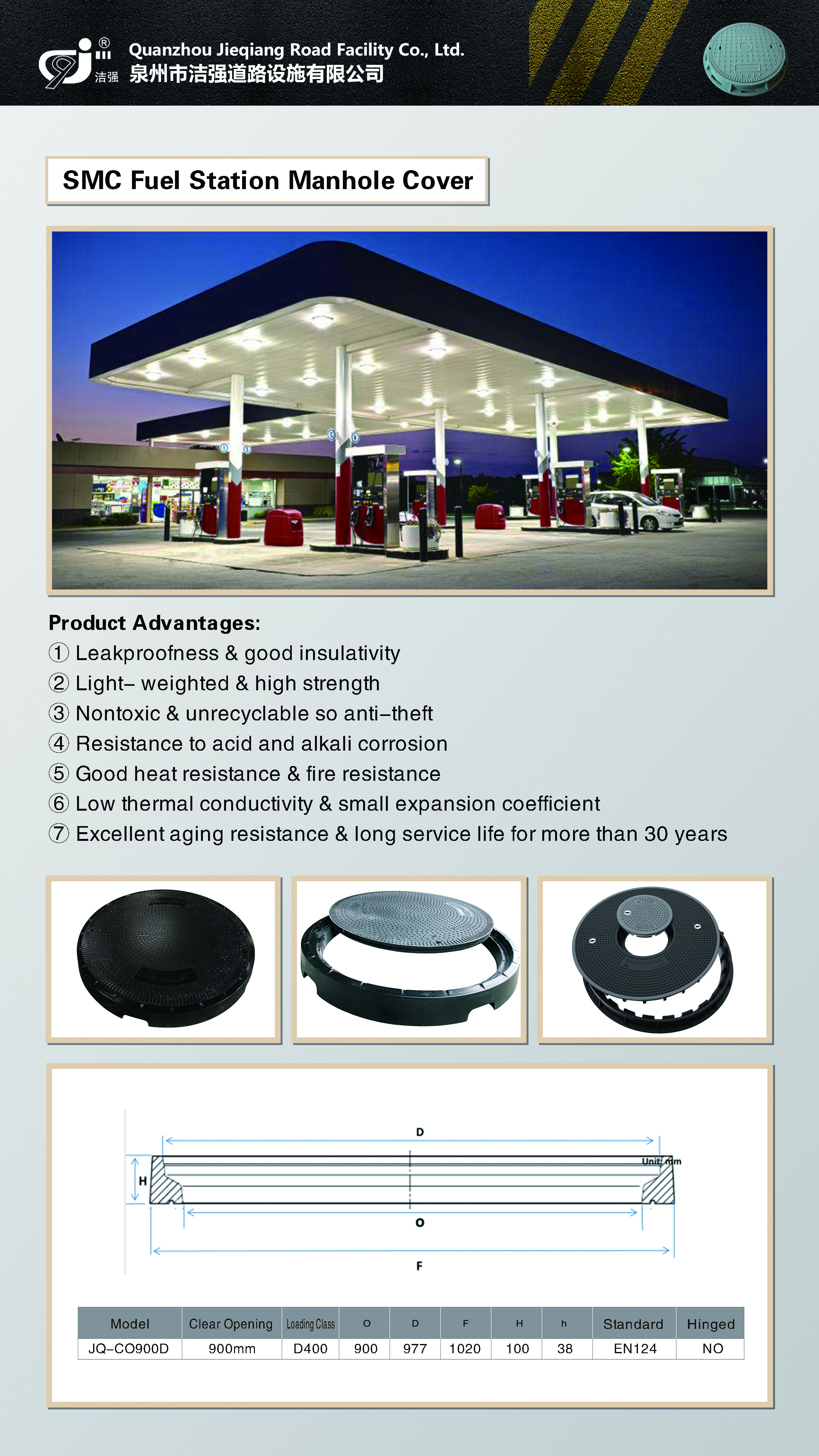

SMC Fuel Station Manhole Covers

JQ SMC gas station manhole covers:

Lightweight

Compared to equivalent standard cast iron manhole covers, SMC manhole covers weigh 50% less. This makes it easier for gas station staff to open the covers for routine maintenance and inspection of fuel tanks.

Gasket Design

A. Prevents water and dust from entering.

B. Stops liquids and toxic gases from leaking out.

C. Protects valves inside the pump and extends their service life.

D. Provides shock absorption, reducing noise when vehicles pass over.

Heavy Load Capacity

Possesses excellent resistance to compression, impact, and bending, capable of meeting the D400 load-bearing requirement necessary for gas stations.

Durability

A. Made from resin and fiberglass, SMC covers resist aging, with a lifespan exceeding 30 years, preventing cracking and fading.

B. Resistant to wear and corrosion, they can withstand asphalt, gasoline and diesel, acids, alkalis, salts, and other chemical substances.

C. SMC covers have good temperature tolerance in both high and low temperatures, ranging from -50°C to 200°C.

Theft Prevention and Safety

A. Equipped with locking mechanisms to prevent unauthorized opening.

B. Features anti-slip patterns on the surface to ensure road safety even under extreme weather conditions.

C. Composite cover plates do not conduct electricity or heat, reducing the risk of fires caused by static electricity at gas stations.

D. SMC material has no recycling value, which helps to prevent theft.

Inspection Port Design

The center of the manhole cover is equipped with an inspection port. Due to its lightweight material, one person can easily open it, facilitating daily inspections, maintenance, and cleaning of fuel tanks by gas station personnel, thus improving work efficiency at the station.