Jieqiang SMC Manhole Cover Pressure Testing: Safety Performance can be seen!

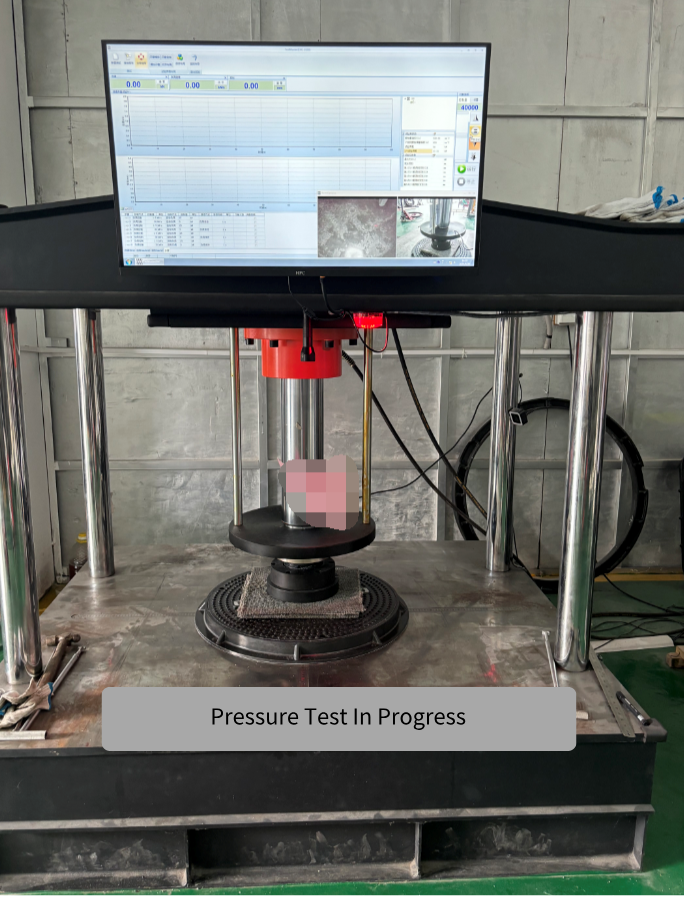

In our factory's pressure testing laboratory, technicians use advanced pressure testing equipment to conduct sample inspections on SMC manhole cover products from each batch of orders. The tests simulate the scenario of vehicles exerting heavy pressure over an extended period.

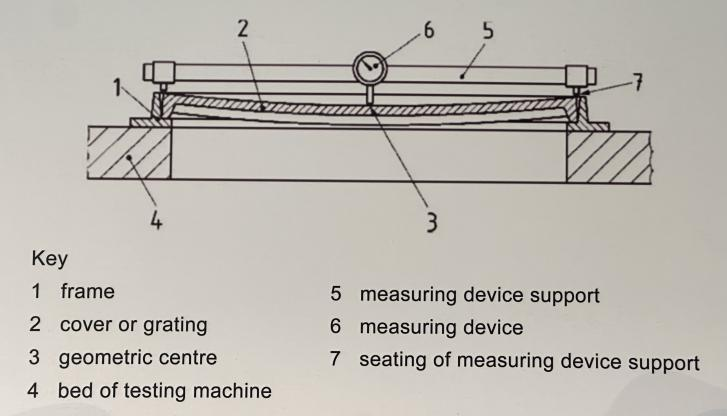

Load Test Procedure:

1. The brand new whole set of SMC manhole cover is prepared, select the corresponding test block (see Table A below), turn on the tester and set the parameters to zero.

2. The test sample shall be placed on the test machine and the frame shall be supported on the bed of the test machine in such a way as to ensure that when the cover or grating is deflected under the test load, it shall remain unsupported, and not in contact with the bed of the test machine.The test block shall be placed on the geometric centre of the cover with its vertical axis perpendicular to the surface of the cover.

3. The load shall be applied at a rate of 1kN/s to 5 kN/s up to 2/3 of the test load, the load on the test specimen is then released. This procedure shall be carried out five times without significant interruption, recording the corresponding deformation each time. Subsequently, perform the final pressurization to the maximum load and maintain the pressure for 30 seconds before releasing it. If destructive testing is required, continue applying pressure until the manhole cover fractures can no longer bear the load, then terminate the pressure application.

4. Turn off the oil pressure system, take out the SMC manhole cover sample, and check the front and back conditions of the whole set of SMC manhole cover.

5. Record shall be made of the condition of the manhole top or gully top after removal of the tests load and a report prepared accordingly.

The test results show that even after being subjected to continuous five applications of two-thirds of the maximum pressure, followed by one application of the full maximum pressure, and maintaining this pressure for 30 seconds, the SMC manhole cover remains intact without any signs of cracking or deformation. This outcome fully demonstrates the advantages of SMC material in terms of compressive strength, durability, and safety.

* During the pressure testing, the Jieqiang SMC manhole cover demonstrated a maximum load-bearing capacity of over 400 kN.

The laboratory pressure tests not only showcase the significant potential of SMC materials in the manufacture of public infrastructure products but also provide more reliable solutions for urban road safety.

"We are very pleased to see our SMC manhole cover products perform so well under such stringent conditions," said the company's managing director in an interview. "This test is not only a validation of our product quality but also an affirmation of the potential of SMC materials." (Click to see our SMC manhole cover !)

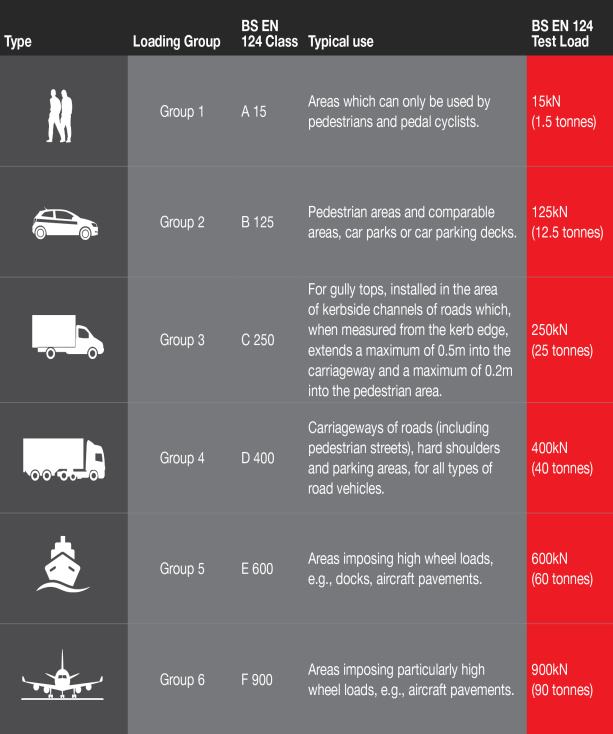

Standard: EN124

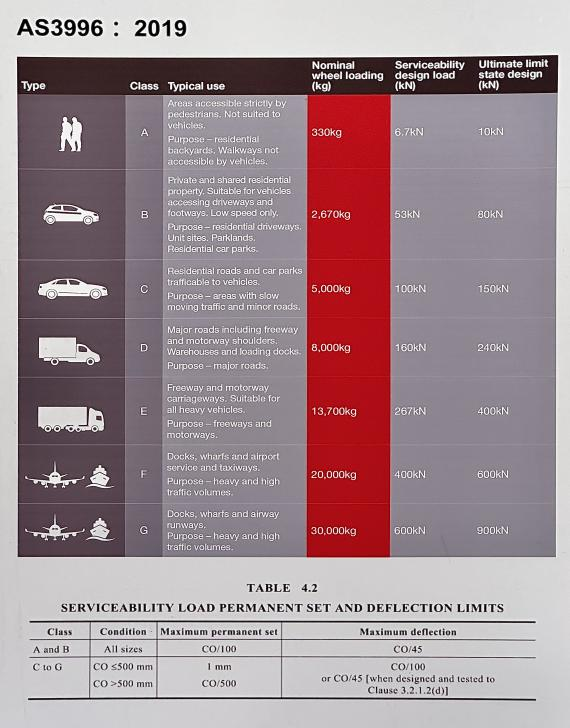

Standard: AS3996:2019